Vertical Integration Strategies for Mid-Market Companies

Vertical integration—acquiring businesses along your supply chain—remains a powerful yet underutilized strategy for mid-market companies seeking competitive advantage. While giants like Apple and Amazon make headlines with their integration moves, companies with revenues between $10 million and $1 billion can strategically implement this approach at manageable scales. The right vertical integration strategy can insulate businesses from supply disruptions, expand profit margins, and create significant barriers to entry for competitors. However, success requires careful assessment of capabilities, market conditions, and long-term strategic alignment rather than following industry trends.

The Strategic Fundamentals of Vertical Integration

Vertical integration involves expanding a company’s operations either upstream toward suppliers or downstream toward distribution channels and customers. Unlike horizontal integration, which focuses on acquiring competitors, vertical moves bring previously external operations in-house. The concept dates back to industrial pioneers like Andrew Carnegie, who owned everything from coal mines to steel mills and shipping lines. Today’s approaches are typically more selective, targeting specific pain points or opportunities along the value chain.

Forward integration moves a company closer to end customers, giving greater control over how products reach the market. This approach works particularly well when distribution channels are fragmented or underserving customer needs. Backward integration, conversely, involves acquiring suppliers or production capabilities, reducing dependency on external vendors while capturing additional margin. The most successful mid-market integration strategies focus on addressing specific vulnerabilities or exploiting distinctive opportunities rather than pursuing control for its own sake.

Financial Considerations Beyond Simple Cost Reduction

While cost savings often drive integration discussions, the financial calculation extends beyond simple margin comparisons. The significant capital requirements of acquisitions or building new capabilities must be weighed against incremental returns. For mid-market companies, particularly those with limited access to capital, opportunity costs loom large—resources dedicated to vertical integration are resources unavailable for other strategic initiatives.

Successful integrators carefully model total costs of ownership, not just immediate production expenses. Many mid-market manufacturers have found that integrating component production yields only modest direct cost savings but dramatically improves quality control and production flexibility. Privately-held window manufacturer Andersen Corporation’s backward integration into vinyl extrusion operations delivered mediocre cost improvements initially but eventually provided critical supply security and quality differentiation as competitors experienced component shortages.

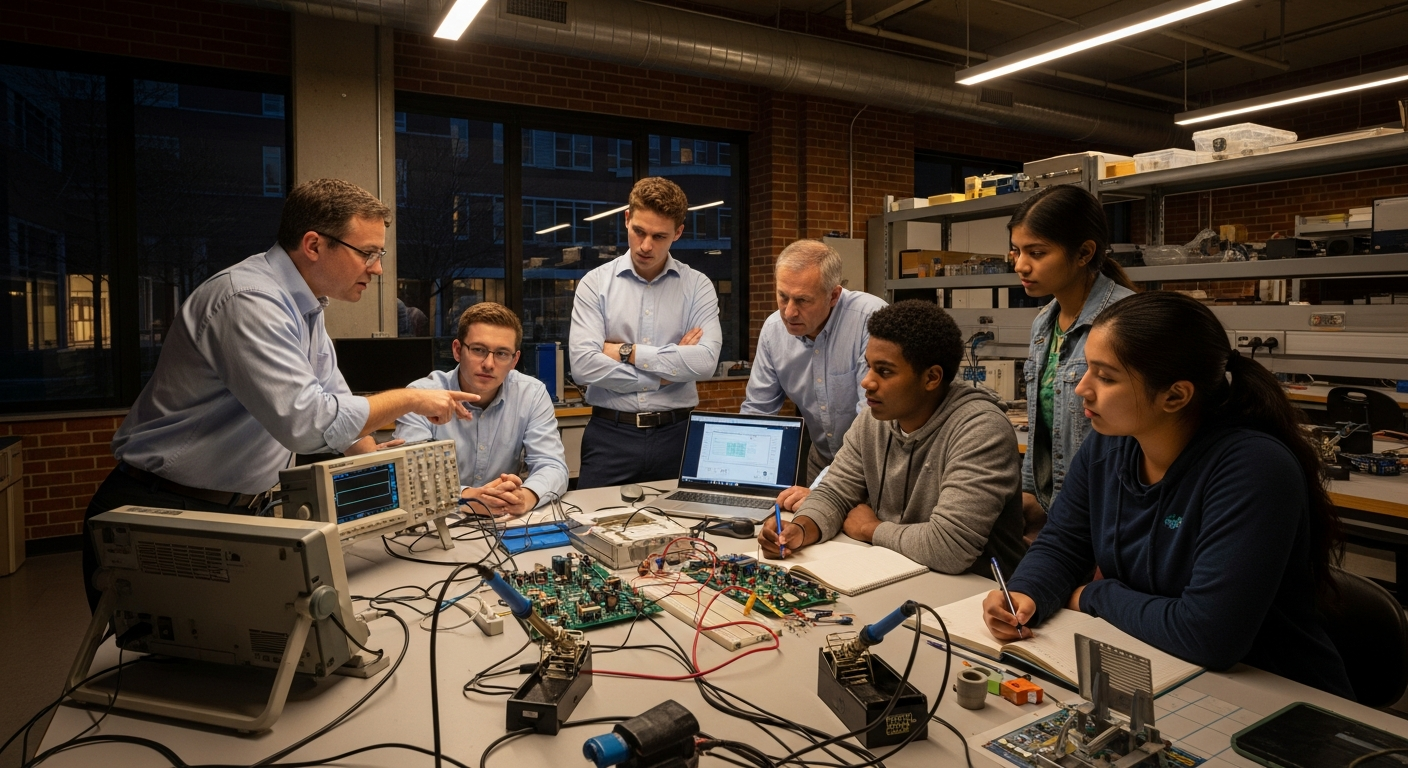

Capability Assessment and Core Competency Alignment

Perhaps the most critical yet overlooked aspect of vertical integration decisions is honest capability assessment. The skills required to successfully operate in adjacent segments of the value chain often differ dramatically from a company’s core competencies. Manufacturing excellence doesn’t automatically translate to distribution expertise. Retail mastery doesn’t ensure successful production management.

The classic cautionary tale remains General Motors’ disastrous 1984 acquisition of Electronic Data Systems. What seemed like a logical step toward integrating emerging technology capabilities became a cultural and operational nightmare as manufacturing executives attempted to manage software developers. Mid-market companies must be particularly cautious as they typically lack the management depth of larger enterprises. Successful integrators start with thorough capability mapping, identifying gaps that would require significant talent acquisition or development before attempting integration moves.

Partial Integration Models for Mid-Market Flexibility

While full vertical integration carries substantial risks, mid-market companies are increasingly adopting partial integration models that deliver strategic benefits with lower capital requirements and operational complexity. Quasi-integration through strategic partnerships, minority investments, or contractual arrangements can secure priority access to suppliers or distribution channels without full ownership burdens.

Wisconsin-based packaging manufacturer Placon Corporation demonstrates this approach effectively. Rather than fully backward integrating into plastic production, Placon established a recycling operation that processes post-consumer plastic into sheet material—a partial backward integration that secures raw material supply while supporting sustainability goals. This targeted approach addresses a specific vulnerability (material access) while avoiding areas where the company lacks expertise (chemical processing). Similar quasi-integration strategies include joint ventures, exclusive supplier arrangements with capital investments, or forward integration through branded storefronts within existing retailers.

Market Dynamics and Competitive Response

Integration decisions cannot be made in competitive isolation. Every strategic move invites market response, particularly when it threatens established players. Vertical moves often trigger defensive counteractions from threatened parties in the value chain. When a mid-market furniture manufacturer integrated forward by opening its own showrooms, it found key retail partners suddenly reducing floor space for its products. The competitive retaliation eliminated much of the anticipated integration benefit.

Timing also critically impacts integration success. Integration during industry consolidation or technological disruption often yields greater advantages than moves during stable periods when relationships and economics are well-established. Mid-market companies should carefully monitor industry inflection points—the shift to e-commerce created opportunities for previously impossible direct-to-consumer models, while supply chain disruptions during 2020-2022 created compelling rationales for backward integration in previously stable supplier markets.

Strategic Implementation Guidelines for Vertical Integration

-

Begin with vulnerability mapping—identify where your business faces greatest supply or distribution risk, as these areas typically offer highest integration returns

-

Calculate integration costs beyond acquisition prices—consider management bandwidth requirements, system integration expenses, and learning curve inefficiencies

-

Consider partial integration first—especially for mid-market companies, minority investments or strategic partnerships often deliver most benefits with less risk

-

Develop clear post-integration governance structures before acquisition—determine how integrated business units will make decisions and resolve competing priorities

-

Create escape mechanisms—establish conditions under which you would divest integrated operations if market conditions change

Vertical integration offers mid-market companies a powerful strategy for securing competitive advantage when approached with clear-eyed analysis rather than industrial nostalgia. By focusing integration efforts on specific vulnerabilities or distinctive capabilities, organizations can capture tangible benefits without overextending resources. The most successful practitioners treat integration not as a destination but as an adaptive strategy, continuously evaluating which functions deliver greater value in-house versus externally sourced. As supply chain resilience concerns remain prominent, selective vertical integration will continue growing in strategic importance for mid-market enterprises seeking sustainable differentiation.