Strategic Waste Management in Manufacturing: Turning Costs into Revenue

Industrial production generates significant waste—often seen as an unavoidable cost center rather than a potential revenue stream. Today's forward-thinking manufacturers are revolutionizing their approach to waste management, transforming traditional disposal methods into profit-generating opportunities. This shift represents more than environmental responsibility; it's becoming a competitive advantage in an increasingly resource-constrained marketplace. By reimagining waste as a valuable resource, companies are discovering innovative pathways to operational efficiency while simultaneously reducing their environmental footprint.

Beyond Traditional Waste Disposal

Conventional waste management in manufacturing has typically focused on compliance and cost minimization. Companies would generate waste, pay for disposal, and consider the matter closed. This linear approach—take, make, dispose—represented a significant financial burden, with waste management often accounting for 4-10% of operating costs in manufacturing operations. Today’s competitive landscape demands a more sophisticated strategy.

Modern waste management frameworks treat manufacturing byproducts as potential resources rather than liabilities. Through materials recovery, upcycling, and industrial symbiosis, companies are finding innovative applications for what was previously discarded. Material that cannot be reused internally can often be sold to other industries as raw material, creating new revenue streams. For example, spent grain from breweries now supplies bakeries and animal feed producers, while textile waste finds new life in composite materials.

The financial implications are significant: companies implementing comprehensive waste recovery programs report average cost reductions of 15-25% in waste management, with some generating additional revenue equivalent to 1-3% of their operating costs—a substantial figure in industries operating on slim margins.

The Economics of Resource Recovery

The business case for strategic waste management extends well beyond simple cost avoidance. When manufacturers systematically analyze their waste streams, they often discover opportunities for material recovery that deliver multiple benefits across the operation.

Resource recovery creates three distinct financial advantages. First, it reduces direct disposal costs, including transportation, landfill fees, and regulatory compliance expenses. Second, it recovers valuable materials that would otherwise require purchase, effectively providing discounted raw materials. Third, it can create entirely new product lines or revenue streams through the sale of recovered materials or byproducts.

Consider the case of a mid-sized food processor that implemented a comprehensive organic waste recovery program. By installing dewatering and composting equipment, they reduced waste disposal costs by 64%, created a premium soil amendment product now sold to local farms, and improved their community standing. The initial $175,000 investment achieved payback in 14 months, with ongoing annual savings and revenue exceeding $230,000.

For manufacturing operations, even modest improvements in material efficiency translate directly to the bottom line. A 5% reduction in material losses can improve profit margins by 1-3 percentage points in many manufacturing sectors—often equivalent to a 10-15% increase in sales volume.

Implementing Strategic Waste Reduction Programs

Successful waste management transformation begins with comprehensive waste stream analysis. This process involves detailed examination of all materials entering and exiting production processes, identifying opportunities for reduction, reuse, or value recovery. Rather than addressing symptoms, this approach targets root causes of waste generation.

The implementation follows a clear hierarchy: first, process optimization to minimize waste creation; second, internal reuse opportunities; third, external markets for byproducts; and finally, improved disposal methods for unavoidable waste. This staged approach ensures companies capture maximum value before considering disposal options.

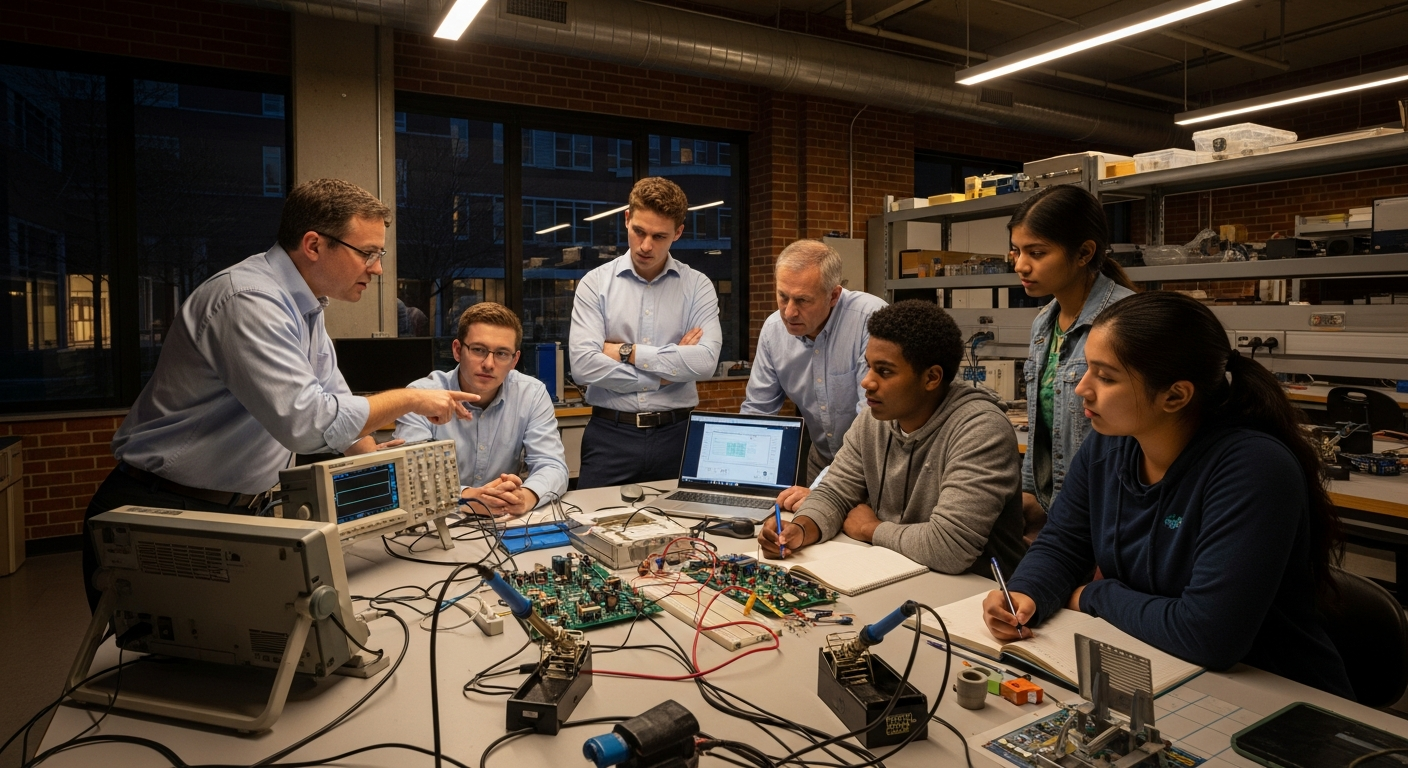

Cross-functional teams prove essential to successful implementation. Engineering identifies process improvements, procurement secures better input materials, marketing explores new applications for byproducts, and finance quantifies benefits. This collaborative approach breaks down the departmental silos that often prevent holistic waste management.

Technology plays an increasingly important role, with real-time monitoring systems tracking material flows and identifying inefficiencies. Advanced analytics help companies predict maintenance needs before they create waste through suboptimal production, while materials databases identify potential buyers for specific waste streams.

Case Study: Chemical Manufacturing Waste Valorization

A specialty chemical manufacturer struggling with hazardous waste disposal costs exemplifies the transformative potential of strategic waste management. Facing rising treatment expenses and environmental compliance challenges, the company initiated a comprehensive waste stream analysis.

The investigation revealed that a key waste stream contained recoverable solvents with potential market value. By installing fractional distillation equipment, the company began recovering 94% of previously discarded solvents. The recovered materials were either reused in production or sold to secondary markets at approximately 60% of virgin material market prices.

The financial impact proved substantial: disposal costs decreased by $1.4 million annually, while recovered material value contributed an additional $850,000 to the bottom line. The capital investment of $3.2 million yielded a 29-month payback period, followed by sustained financial benefits. Beyond direct financial gains, the company significantly reduced its environmental liability and improved its sustainability metrics, strengthening relationships with environmentally conscious customers.

This case demonstrates how technical innovation, combined with market awareness, can transform waste management from an environmental compliance necessity into a strategic business advantage that simultaneously advances sustainability goals and financial performance.

Building a Waste Management Strategy

Developing an effective waste management strategy requires systematic planning and organization-wide commitment. The process begins with establishing baseline metrics on current waste generation, disposal costs, and environmental impact. Without clear measurement, companies cannot demonstrate improvement or justify further investments.

Leadership engagement proves critical for success. When executives champion waste reduction as a strategic priority rather than a compliance exercise, they create the cultural conditions necessary for innovation. Companies that integrate waste reduction targets into performance metrics and bonus structures report 40-60% greater success rates in their programs.

Investment criteria for waste management initiatives often differ from standard capital projects. Since many benefits extend beyond direct cost savings to include regulatory compliance, risk reduction, and brand protection, companies should apply more comprehensive evaluation frameworks. Leading organizations are adopting triple bottom line assessment models that value environmental and social benefits alongside financial returns.

Educational initiatives ensure that employees at all levels understand waste reduction objectives and their role in achieving them. Some manufacturers have implemented suggestion programs that reward employees for waste reduction ideas, generating both engagement and practical innovations.

Key Implementation Strategies for Manufacturing Success

-

Conduct material flow analysis to identify highest-value recovery opportunities

-

Prioritize interventions based on both financial return and implementation difficulty

-

Establish partnerships with other industries that can use your byproducts as raw materials

-

Implement real-time monitoring systems to identify process inefficiencies before they generate waste

-

Consider leasing equipment rather than purchasing to reduce capital requirements for waste recovery systems

-

Create clear metrics and regular reporting structures to maintain momentum and demonstrate progress

-

Engage equipment vendors as technical partners rather than simple suppliers

-

Develop waste reduction competencies through targeted training programs

Strategic waste management represents one of the few remaining areas where manufacturing companies can simultaneously reduce costs, generate revenue, and improve environmental performance. By treating waste as a resource rather than a disposal problem, forward-thinking manufacturers are discovering powerful competitive advantages. The transition requires investment, technical innovation, and organizational commitment, but companies that successfully implement comprehensive waste recovery programs are positioning themselves for sustained success in an increasingly resource-constrained business environment.