Hydrogen Internal Combustion Engines: The Clean Alternative You Haven't Heard About

In the search for cleaner automotive propulsion systems, hydrogen internal combustion engines represent an overlooked middle ground between conventional gasoline engines and radical new technologies. While electric powertrains dominate environmental discussions, hydrogen combustion offers a fascinating bridge technology that combines familiar engineering with zero-carbon potential. This approach uses modified conventional engines to burn hydrogen instead of gasoline, producing only water vapor as exhaust. The technology merits serious consideration in our transitional energy landscape, particularly for heavy-duty applications where battery weight presents significant challenges. Automakers like BMW and Toyota have already developed functional prototypes, demonstrating the viability of this underappreciated technology.

The Hydrogen Combustion Principle

Hydrogen internal combustion engines operate on the same fundamental principles as traditional gasoline engines, with fuel being burned in cylinders to create expanding gases that drive pistons and produce mechanical energy. The primary difference lies in the fuel itself. Hydrogen has significantly different combustion properties than gasoline - it ignites more easily, burns faster, and requires different air-fuel ratios. When hydrogen burns, it combines with oxygen to produce primarily water vapor, eliminating the carbon dioxide emissions inherent in fossil fuel combustion. The energy density of hydrogen also presents advantages, with hydrogen containing approximately three times the energy by weight compared to gasoline, though it requires more volume storage space due to its lower density at standard pressure.

The combustion behavior of hydrogen presents unique engineering challenges. Its wide flammability range (4-75% concentration in air) makes it more versatile but requires precise control. The flame speed of hydrogen is approximately seven times faster than gasoline, necessitating modified ignition timing. These properties demand redesigned engine components, including specialized fuel injection systems, modified cylinder heads, and different materials to prevent hydrogen embrittlement - a process where hydrogen atoms penetrate metal structures, causing them to become brittle over time.

Historical Development and Early Prototypes

The concept of hydrogen-powered internal combustion is not new, dating back to experiments in the early 1800s. In 1806, François Isaac de Rivaz built the first hydrogen-powered internal combustion engine, though it was incredibly primitive by modern standards. More serious development began in the 1970s during the oil crisis when automakers began exploring alternative fuels. BMW became a pioneer in this field, developing its first hydrogen combustion prototype in 1979 based on a modified 520i sedan. This experimental vehicle could switch between gasoline and hydrogen operation, demonstrating the concept’s basic feasibility.

Throughout the 1980s and 1990s, BMW continued refining its hydrogen combustion technology, culminating in the Hydrogen 7 luxury sedan unveiled in 2006. Based on the 760i, this vehicle featured a dual-fuel V12 engine capable of running on either hydrogen or gasoline. BMW produced approximately 100 Hydrogen 7 vehicles for evaluation purposes, placing them with celebrities and politicians to raise awareness. Around the same time, Mazda experimented with hydrogen rotary engines, creating the RX-8 Hydrogen RE in 2003, which utilized the unique characteristics of the Wankel rotary engine to accommodate hydrogen fuel. These early prototypes demonstrated that conventional engine architecture could be adapted to burn hydrogen with relatively modest modifications.

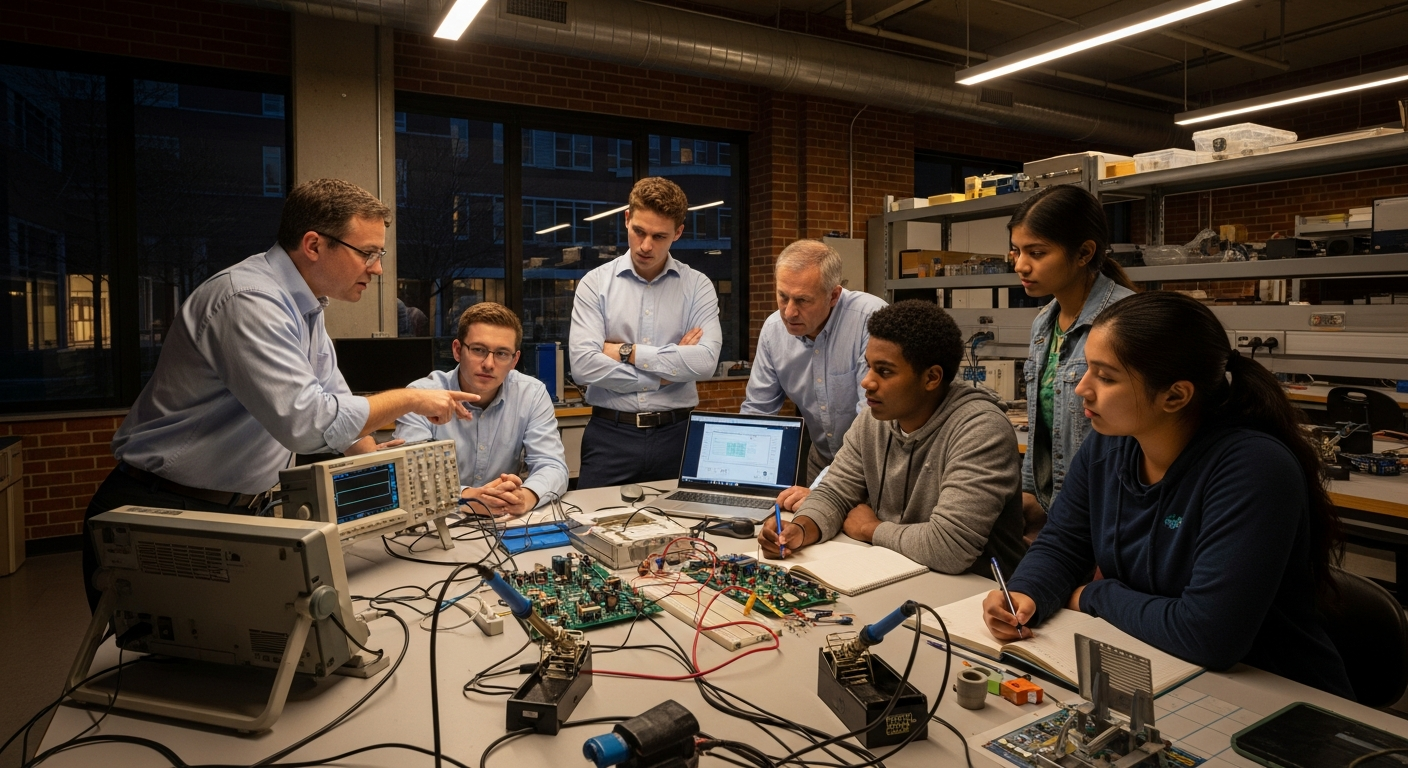

Modern Engineering Approaches

Contemporary hydrogen combustion engine development has benefited significantly from advances in computational modeling, materials science, and fuel system design. Modern direct injection systems allow hydrogen to be precisely introduced into the combustion chamber at pressures exceeding 700 bar, greatly improving combustion efficiency and power density. Advanced electronic control units continuously optimize the air-fuel mixture based on real-time sensor data, maintaining ideal combustion parameters across all operating conditions.

Material science has also addressed many early challenges, with specialized alloys now available that resist hydrogen embrittlement. Turbocharging and supercharging technologies have been adapted specifically for hydrogen applications, compensating for the lower volumetric energy density of the fuel. Cooling systems have been redesigned to manage the higher combustion temperatures that hydrogen produces compared to gasoline. The result of these engineering advances is hydrogen combustion engines that approach the power output and drivability of conventional gasoline engines while producing virtually zero harmful emissions.

Toyota has emerged as a modern leader in hydrogen combustion technology, having developed a 1.6-liter three-cylinder turbocharged hydrogen engine that powers a racing version of its Corolla Sport. This engine has successfully competed in Japan’s Super Taikyu endurance racing series since 2021, proving the technology’s reliability and performance potential. The racing program serves as both a development platform and a showcase for hydrogen combustion technology, demonstrating that environmental responsibility need not come at the expense of driving excitement.

Advantages Over Alternative Clean Technologies

Hydrogen combustion engines offer several distinct advantages compared to both battery electric vehicles and hydrogen fuel cells. Perhaps most significantly, they leverage existing manufacturing infrastructure and expertise. Major automakers have invested billions in engine production facilities and possess deep institutional knowledge about internal combustion design. Converting these facilities to produce hydrogen combustion engines requires far less capital investment than building entirely new electric powertrain factories.

From a consumer perspective, hydrogen engines deliver a familiar driving experience with the sound, vibration, and immediate throttle response that many enthusiasts appreciate. They also eliminate range anxiety concerns associated with battery electric vehicles, as refueling takes just minutes rather than the extended charging times required for large battery packs. For demanding applications like heavy trucking, construction equipment, and marine propulsion, hydrogen combustion potentially offers better power density than battery systems, which become prohibitively heavy at scale.

Compared to hydrogen fuel cells, combustion engines have significant cost advantages. Fuel cells require expensive platinum catalysts and specialized membrane technology, while hydrogen combustion engines are fundamentally similar to existing mass-produced engines. This cost differential makes hydrogen combustion potentially more viable for widespread adoption in markets where price sensitivity is a major factor. Additionally, hydrogen combustion engines tend to be more durable and tolerant of fuel impurities than fuel cells, which require extremely pure hydrogen to prevent catalyst poisoning.

Challenges and Future Prospects

Despite its promise, hydrogen combustion technology faces substantial hurdles to widespread adoption. The most pressing challenge remains hydrogen infrastructure - the lack of widespread refueling stations creates a classic chicken-and-egg problem that has hindered all hydrogen vehicle technologies. Manufacturing and distributing hydrogen also presents difficulties, as current production methods either generate significant carbon emissions (gray hydrogen from natural gas) or require substantial energy inputs (green hydrogen from electrolysis). The volumetric efficiency challenge also remains; even with high-pressure storage tanks, hydrogen requires approximately four times the volume of gasoline for equivalent energy content.

Looking forward, hydrogen combustion engines may find their most promising applications in commercial transportation and industrial sectors where battery weight becomes prohibitive. Heavy-duty trucks, buses, construction equipment, and ships could all benefit from hydrogen combustion technology, particularly as green hydrogen production scales up through renewable energy sources. Some manufacturers are exploring dual-fuel approaches that allow engines to operate on either hydrogen or conventional fuels, providing flexibility during the transition period while hydrogen infrastructure develops.

Research continues into advanced combustion strategies specifically optimized for hydrogen. Pre-chamber ignition systems, which initiate combustion in a small chamber before propagating to the main cylinder, show particular promise for increasing efficiency and reducing the formation of nitrogen oxides - the one potentially significant pollutant from hydrogen combustion. With continued development, hydrogen internal combustion engines could evolve from niche curiosities into practical solutions for decarbonizing segments of transportation where electrification faces significant challenges.