E-Textiles: The Fabric of Computing's Future

The collision of technology and textiles has birthed an entirely new frontier of innovation: electronic textiles. These smart fabrics and garments incorporate conductive threads, miniaturized sensors, and flexible circuits directly into wearable materials, transforming everyday clothing into interactive platforms. As computing continues to search for its next form factor beyond smartphones and wearables, e-textiles represent a fascinating evolution where technology disappears into the very fabric of our clothing. The implications span from fitness tracking to medical monitoring, military applications to high-fashion statements – all woven seamlessly into the clothes on our backs.

The Threads That Connect Us

Electronic textiles – often shortened to e-textiles or smart textiles – represent a fascinating convergence of traditional fabric manufacturing and modern electronics. Unlike simply attaching devices to clothing, true e-textiles integrate electronic capabilities directly into the fabric structure. This integration happens through various methods: conductive threads woven alongside traditional fibers, electronic components printed directly onto fabric using conductive inks, or the incorporation of miniaturized flexible circuits embedded between layers of material.

The history of e-textiles traces back further than many realize. In the 1990s, researchers at MIT’s Media Lab began pioneering work on what they called “computational garments,” but the technology remained largely experimental. The 2000s saw advancements in conductive materials and manufacturing techniques that made integration more practical. Today, these smart fabrics incorporate technologies including sensors (temperature, pressure, stretch), actuators (shape-changing elements), power management systems, and communication modules – all while maintaining the flexibility, comfort and washability we expect from everyday clothing.

Smart Clothing’s Commercial Breakthrough

While prototypes and niche applications have existed for years, e-textiles are now approaching mainstream commercial viability. Major sportswear companies like Adidas, Nike and Under Armour have all invested in developing smart garments that can track metrics like heart rate, breathing patterns, and muscle activation without the need for separate wearable devices. Finnish company Myontec offers compression shorts with embedded electromyography sensors that analyze muscle performance for athletes and physical therapy patients.

Perhaps the most significant breakthrough comes from Google’s Project Jacquard, a collaboration with Levi’s that produced the Commuter Trucker Jacket. This denim jacket features a touch-sensitive area on the cuff that allows wearers to control music, navigation, and calls with gestures. Priced initially at $350 when launched in 2017, this represented one of the first mass-market attempts at bringing e-textiles to consumers. Updated versions have reduced in price to around $200, signaling the technology’s gradual move toward affordability.

The healthcare sector presents another promising avenue. Companies like Hexoskin produce biometric shirts that continuously monitor vital signs for patients with chronic conditions. These garments, ranging from $300-500, can reduce hospital visits by enabling remote monitoring while patients maintain normal daily activities – a value proposition that extends beyond mere convenience to significant healthcare cost savings.

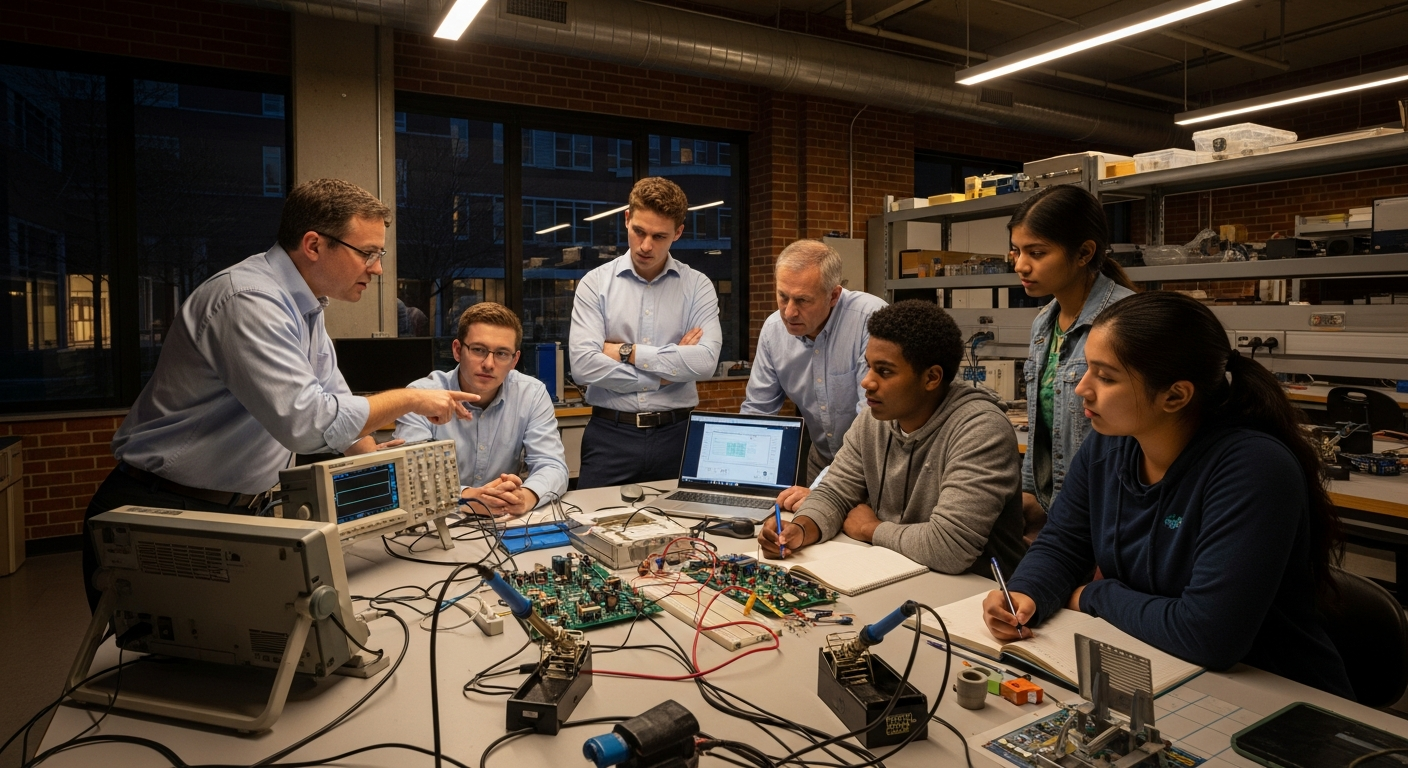

Breaking Technical Barriers

The technical challenges facing e-textile development have been substantial. First is the fundamental mismatch between electronics (traditionally rigid, water-sensitive) and textiles (flexible, washable, expected to withstand years of wear). Engineers have had to completely reimagine electronic components to function within fabric constraints.

Power supply remains perhaps the most significant hurdle. While flexible batteries exist, they still present limitations in capacity, charging methods, and safety. Promising alternatives include energy harvesting technologies that capture power from body heat, movement, or ambient radio signals. Researchers at Georgia Tech have demonstrated fabric that generates electricity from sunlight and motion, potentially eliminating the need for separate batteries altogether.

Durability presents another challenge. Electronic elements must withstand stretching, folding, washing, and ordinary wear. Recent developments in encapsulation technologies protect sensitive components with specialized polymers that repel water while remaining flexible. Manufacturing processes have also evolved to withstand industrial textile production methods – high temperatures, tension, and chemical treatments once incompatible with electronics.

Fashioning Tech Identity

Beyond technical functionality, e-textiles face cultural and aesthetic hurdles. Smart clothing must balance technological capability with fashion sensibility – a challenge that has doomed many wearable devices that prioritized function over form. Designer Anouk Wipprecht represents the artistic potential, creating dramatic tech-infused fashion pieces like her “Spider Dress” with animatronic arms that respond to proximity sensors.

For mainstream adoption, however, e-textiles need to be virtually indistinguishable from regular clothing. Several fashion schools now offer specialized programs combining textile design with electronics, producing graduates capable of bridging the technical and aesthetic requirements. Major fashion brands like Ralph Lauren have experimented with smart clothing lines, demonstrating the potential for technology that enhances rather than compromises style identity.

The psychological element cannot be overlooked – clothing represents one of our most personal expressions of identity. For e-textiles to succeed commercially, they must respect this intimate relationship while offering meaningful functionality that justifies their increased cost. Current price premiums of 30-200% over comparable “dumb” clothing remain a significant adoption barrier for most consumers.

The Woven Future

Looking ahead, e-textiles appear positioned to evolve in several important directions. Environmental sensing capabilities will expand, with fabrics that can detect pollutants, UV levels, and even potential biohazards. Communication between garments will enable new social interactions – imagine concert t-shirts that synchronize lighting effects across thousands of attendees.

Healthcare applications offer the clearest path to widespread adoption. Smart bandages that monitor wound healing, socks that prevent diabetic ulcers through pressure sensing, and shirts that detect irregular heartbeats before they become dangerous all provide compelling value propositions worth their premium pricing. The aging global population creates particular demand for unobtrusive monitoring technologies that preserve dignity and independence.

Perhaps most intriguing is the potential for e-textiles to transform from passive monitoring devices to active therapeutic tools. Researchers at Harvard have developed fabrics with piezoelectric elements that provide gentle electrical stimulation to muscles during rehabilitation. Others are exploring garments that adjust compression levels dynamically based on body feedback or deliver medication through the skin only when sensors detect it’s needed.

As manufacturing scales and component costs decline, smart textiles will gradually permeate wardrobes not as novelties but as expected features – similar to how smartphones evolved from luxury items to necessities. The true success of e-textiles will come not when they’re marketed as technology, but when they’re simply seen as better clothing – the natural evolution of an industry that has continuously incorporated new materials and techniques throughout human history.