Demand-Based Facility Scaling for Competitive Agility

Achieving sustainable growth while maintaining resource efficiency requires manufacturers and industrial enterprises to reimagine their approach to facilities management. Traditional models of maintaining large, fixed physical footprints are giving way to more responsive, demand-based scaling strategies. These innovative approaches help companies minimize overhead during downturns while providing swift expansion capabilities when market opportunities arise. By implementing modular design principles and creating flexible operational frameworks, forward-thinking businesses are revolutionizing how industrial space adapts to changing conditions. Companies embracing these dynamic facility models are reporting significant improvements in capital efficiency while gaining competitive advantages in increasingly volatile markets.

Understanding the Shift from Fixed to Flexible Facilities

Industrial facility planning has historically operated on assumptions of steady growth and long-term capacity forecasts. For most of the 20th century, manufacturing giants constructed massive, permanent facilities designed to operate at consistent production levels for decades. This approach created significant challenges during economic downturns when fixed costs continued while revenue declined. The oil crisis of the 1970s first exposed the vulnerabilities of inflexible facilities, forcing many manufacturers to maintain underutilized spaces at great expense. By the early 2000s, leading companies began questioning this paradigm, seeking more adaptable approaches to their physical infrastructure.

Demand-based facility scaling represents a fundamental shift in industrial infrastructure planning. Rather than building permanent structures sized for maximum anticipated capacity, companies design modular, reconfigurable spaces that efficiently expand or contract based on current needs. This approach involves both physical infrastructure considerations and operational models that support variable production environments. The concept draws inspiration from cloud computing’s “elasticity” principle, where resources scale automatically to match demand. When applied to physical facilities, this principle creates industrial spaces that maintain optimal efficiency regardless of production volume fluctuations.

Modular Design Principles for Adaptive Manufacturing

Modular facility design serves as the foundation for effective demand-based scaling. Unlike traditional industrial buildings constructed as single, permanent entities, modular facilities consist of standardized, interchangeable components that can be assembled, reconfigured, or relocated as needed. These designs typically feature standardized connection points for utilities, standardized bay dimensions, and infrastructure systems designed for expansion. Leading manufacturers now incorporate grid-based floor plans with movable interior walls, raised access flooring for flexible utility routing, and structural systems designed to accommodate vertical expansion.

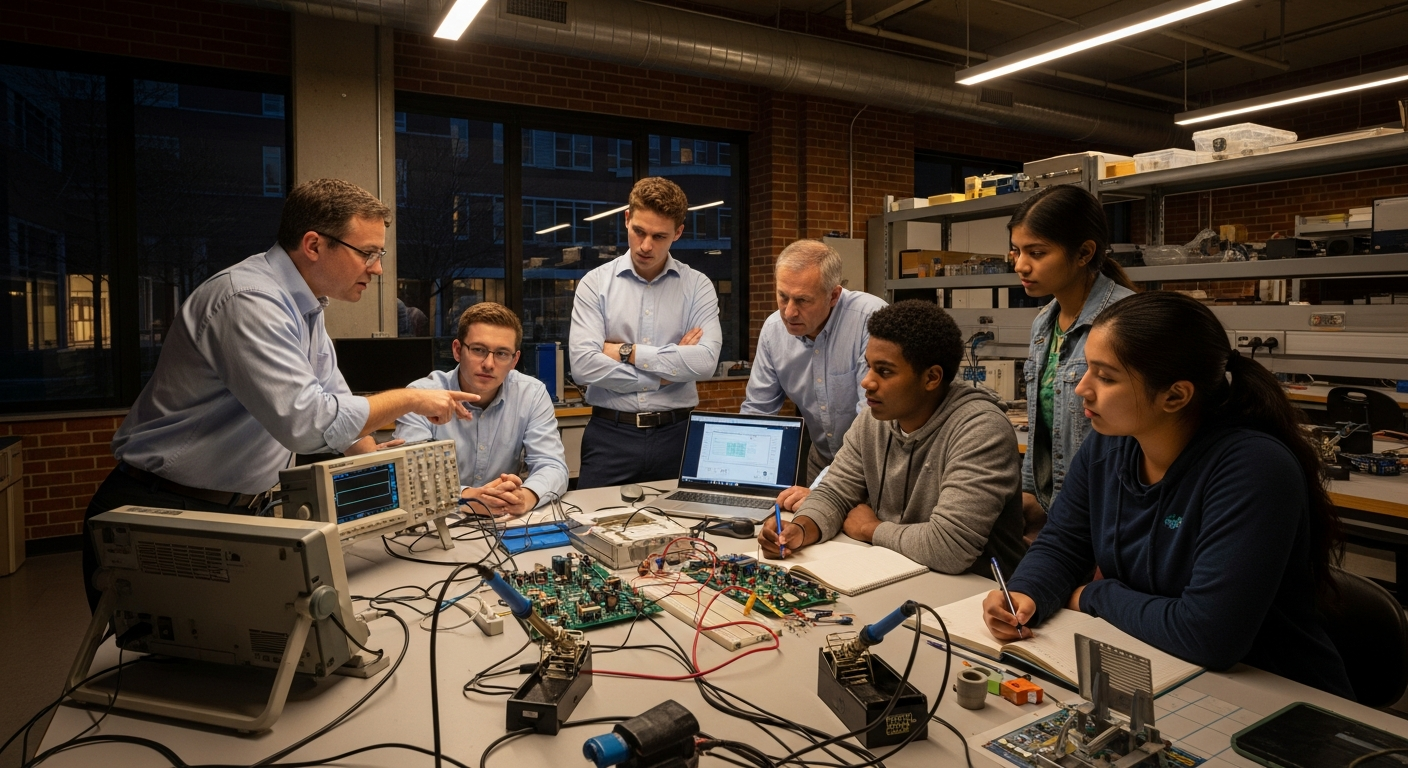

The implementation of modular facilities requires specialized architectural and engineering expertise. Successful designs incorporate “plug-and-play” utility connections where production equipment can be quickly installed or removed without extensive modifications. Structural considerations include load-bearing systems that support future expansion without overbuilding initially. Mechanical systems utilize distributed approaches rather than centralized designs, allowing sections to operate independently as needed. Companies like Assa Abloy and Flex have pioneered these approaches, creating production environments that can expand production capacity by 40% without significant construction disruption.

Dynamic Resource Allocation Strategies

Beyond physical infrastructure, demand-based facility scaling requires sophisticated approaches to resource allocation. Traditional manufacturing models often dedicate specific equipment and personnel to product lines permanently, creating efficiency during steady production but inflexibility during changes. Modern scaling approaches instead utilize resource pooling strategies where equipment, personnel, and materials flow to areas of highest demand. This model requires standardized interfaces between production cells, cross-trained staff, and management systems capable of real-time optimization.

Resource allocation in scaled facilities operates through several mechanisms. First, equipment selection prioritizes multi-purpose machinery that can be reconfigured for different products rather than single-purpose tools. Second, workforce management incorporates skills matrices and rapid training modules to ensure personnel can shift between production types. Third, inventory systems utilize centralized storage with automated retrieval systems that support multiple production areas rather than dedicated stockrooms. Companies implementing these strategies report 15-30% improvements in overall equipment effectiveness (OEE) and significant reductions in response time when market demands shift.

Financial Models Supporting Scaling Flexibility

Traditional facility financing models have centered around long-term capital investments with fixed depreciation schedules and steady-state operational costs. These approaches reward stability but penalize flexibility. Modern facility scaling requires alternative financial frameworks that recognize the value of adaptability while managing investment risk. Leading companies now implement tiered investment strategies where core infrastructure receives traditional long-term financing while adaptable components use alternative models like equipment leasing, vendor-managed spaces, or consumption-based payment structures.

The financial benefits of scaled facilities emerge during market volatility. Companies utilizing traditional facilities typically maintain 70-80% of their costs during 50% production declines, creating significant margin pressure. In contrast, companies with scaled facilities can reduce costs proportionally to production decreases. This difference becomes particularly important during supply chain disruptions or rapid market shifts. Financial analysis shows that while initial implementation costs for scaled facilities may be 10-15% higher than traditional approaches, the lifetime cost advantages typically exceed 25% when measured across full business cycles.

Implementation Roadmap for Transitioning Organizations

Organizations seeking to transition from traditional fixed facilities to demand-based scaling models face significant implementation challenges. The transition requires coordinated changes across physical infrastructure, operational procedures, workforce capabilities, and financial structures. Successful transformations typically begin with pilot programs in selected production areas rather than facility-wide implementations. These pilots allow organizations to refine approaches and build internal expertise before broader deployment.

Implementing scaled facilities requires specific leadership approaches focused on change management and systems thinking. First, organizations must establish clear metrics that value flexibility alongside traditional efficiency measures. Second, cross-functional implementation teams need authority to redesign processes across departmental boundaries. Third, workforce engagement programs must address the cultural shift from stability to adaptability. Companies like ABB and Schneider Electric have successfully implemented phased transitions where portions of existing facilities convert to scalable models while maintaining production, gradually expanding the approach as benefits materialize.

Strategic Implementation Guidelines for Facility Scaling

-

Conduct comprehensive flexibility audits of existing facilities before beginning transformation to identify current constraints and opportunities

-

Develop standardized equipment specifications that prioritize reconfigurability and multi-purpose capabilities over single-function optimization

-

Implement modular utility distribution systems with excess capacity at junction points rather than throughout the system

-

Create financial tracking mechanisms that measure both utilization efficiency and scaling response capabilities

-

Establish vendor partnerships specifically designed around equipment mobility and rapid reconfiguration support

Demand-based facility scaling represents an essential evolution in industrial infrastructure strategy. As market volatility increases and product lifecycles shorten, companies can no longer afford the luxury of static, inflexible production environments. By implementing modular physical designs, dynamic resource allocation systems, and appropriate financial models, organizations create sustainable competitive advantages through operational agility. While the transition requires significant investment in both capital and organizational capability, the resulting adaptability provides crucial protection against market disruptions while enabling rapid response to emerging opportunities.