Biomimicry in Manufacturing: Nature-Inspired Production Innovations

The integration of biomimicry principles into manufacturing operations represents a transformative approach for modern industrial enterprises seeking sustainable and efficient production methods. This revolutionary design philosophy draws inspiration from nature's 3.8 billion years of evolutionary refinement to solve complex industrial challenges. Forward-thinking manufacturers are increasingly examining natural processes and structures to reimagine everything from product design to factory floor operations. The systematic application of biological principles to human industrial systems has proven particularly valuable as companies face mounting pressure to reduce environmental footprints while maintaining competitive advantages. Early adopters of biomimetic manufacturing have already demonstrated remarkable improvements in resource efficiency, waste reduction, and product performance across diverse sectors.

Industrial design and manufacturing processes traditionally relied on linear, resource-intensive methods that often generate significant waste and environmental impact. Biomimicry offers a fundamentally different paradigm—one where natural systems’ circular, adaptive, and resilient qualities inform more sustainable production approaches.

Foundational Principles of Nature-Based Manufacturing

Biomimicry in manufacturing encompasses three distinct levels of implementation: mimicking natural forms, processes, and ecosystems. At the form level, manufacturers adopt structural elements from nature, such as hexagonal patterns inspired by honeycomb structures to create lightweight yet strong materials. Process-level biomimicry involves replicating nature’s methods, like self-assembly techniques modeled after protein folding. The most sophisticated application occurs at the ecosystem level, where entire production systems mimic natural cycles to eliminate waste. These principles have revolutionized industries from aerospace to consumer products manufacturing.

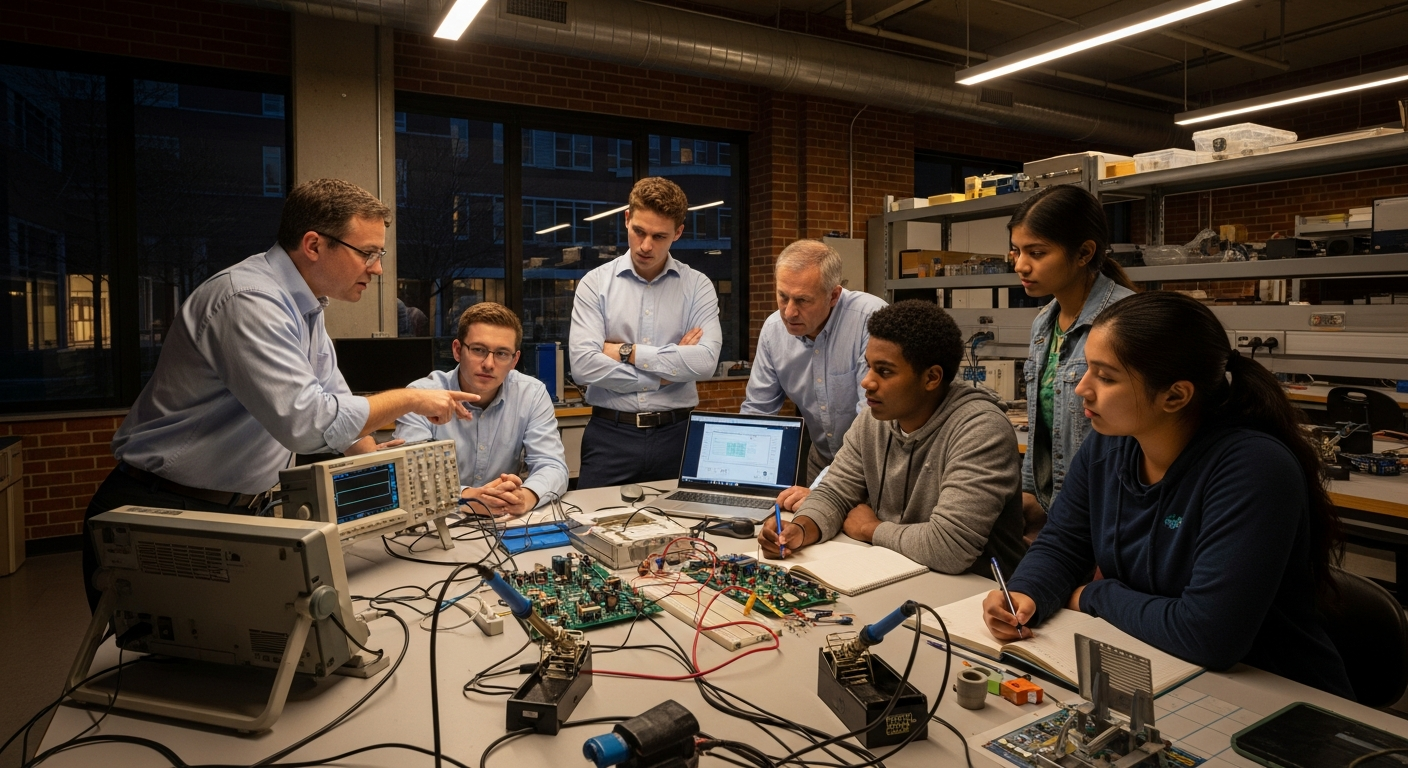

The transition to biomimetic approaches requires significant changes in engineering mindsets. Traditional manufacturing focuses on conquering natural limitations, while biomimicry seeks to learn from and adapt to natural constraints. This philosophical shift demands cross-disciplinary collaboration between biologists, engineers, and designers. Companies implementing these approaches report that initial development investments typically yield substantial long-term returns through reduced material costs, energy savings, and innovative product differentiation that appeals to environmentally conscious consumers.

Material Innovation Through Biological Models

Nature-inspired materials represent one of the most commercially successful applications of biomimicry in manufacturing. Velcro, perhaps the most recognized biomimetic product, emerged from Swiss engineer George de Mestral’s observation of burdock burrs clinging to his dog’s fur. Modern applications continue this tradition with remarkable complexity. Materials scientists have developed self-cleaning surfaces based on the lotus leaf’s microstructure, enabling products that require less maintenance and fewer cleaning chemicals. Fiber manufacturers have replicated spider silk’s remarkable combination of strength, elasticity, and lightweight properties to create high-performance textiles and composite materials with applications ranging from athletic apparel to automotive components.

Structural color represents another breakthrough area, where manufacturers mimic butterfly wings’ iridescent qualities without chemical dyes. This technique produces vibrant, fade-resistant colors while eliminating toxic pigments from production processes. Similarly, sharkskin-inspired surfaces that reduce drag and prevent bacterial adhesion have transformed everything from medical device manufacturing to commercial aircraft production. These innovations demonstrate how examining natural materials at the nano and microscale can yield significant manufacturing advantages while reducing environmental impact.

Process Optimization Using Natural Systems

Beyond materials innovation, biomimicry offers powerful models for reimagining fundamental manufacturing processes. Companies have studied termite mound ventilation to develop passive cooling systems for factories, reducing energy consumption by up to 40% compared to conventional HVAC approaches. Distribution networks modeled after vascular systems in plants and animals have optimized material flow through production facilities, minimizing bottlenecks and maximizing efficiency. Self-healing mechanisms inspired by biological tissue repair have enabled the development of polymers and composites that automatically address microfractures, extending product lifecycles and reducing replacement costs.

Manufacturing scheduling systems increasingly incorporate swarm intelligence principles derived from ant and bee colonies. These algorithms enable dynamic production planning that adapts to changing conditions more efficiently than traditional linear scheduling. Water conservation techniques based on desert organisms’ moisture collection mechanisms have significantly reduced fluid requirements in manufacturing processes. Perhaps most impressively, some manufacturers have successfully implemented closed-loop production systems modeled after forest ecosystems, where waste from one process becomes input for another, dramatically reducing both resource consumption and disposal costs.

Competitive Advantages and Market Differentiation

Organizations embracing biomimicry have documented substantial business benefits beyond operational improvements. A comprehensive study of biomimetic manufacturing implementations across 217 companies revealed average material cost reductions of 23% compared to conventional approaches. Products developed using nature-inspired design processes typically outperform traditional alternatives in durability tests by 30-45%, creating compelling value propositions for both industrial and consumer markets. Additionally, these companies report significant reductions in regulatory compliance costs related to hazardous materials and waste disposal.

Market analysis indicates growing consumer preference for products manufactured using biomimetic approaches, particularly among younger demographic segments. Companies effectively communicating their nature-inspired innovations typically command premium pricing positions while building stronger brand loyalty. Intellectual property portfolios featuring biomimetic innovations demonstrate higher valuation multiples during investment rounds and acquisition discussions. These factors contribute to biomimicry’s emergence as a strategic differentiator in competitive manufacturing landscapes, where traditional cost-cutting approaches increasingly yield diminishing returns.

Implementation Challenges and Future Directions

Despite its potential, widespread adoption of biomimetic manufacturing faces several significant hurdles. The interdisciplinary expertise required—spanning biology, engineering, materials science, and manufacturing—remains relatively scarce in industrial settings. Organizations successful in this domain typically establish dedicated innovation teams that include specialists from diverse fields, often partnering with academic institutions to access specialized knowledge. Initial implementation costs can appear prohibitive when evaluated through traditional ROI frameworks that fail to account for lifecycle benefits and downstream savings.

Regulatory frameworks designed for conventional manufacturing sometimes create unintended barriers to biomimetic approaches, particularly regarding novel materials or processes lacking historical precedent. Forward-thinking manufacturers have addressed these challenges through strategic demonstration projects that build internal expertise while generating quantifiable success metrics. As implementation accelerates, emerging technologies like advanced computational modeling, digital twins, and additive manufacturing are dramatically expanding biomimicry’s potential applications. These tools enable rapid prototyping and testing of nature-inspired solutions that would have been impractical just a decade ago, suggesting biomimetic manufacturing will become increasingly mainstream over the next five years.

Strategic Implementation Guidelines for Manufacturers

-

Begin with small-scale pilot projects focused on specific pain points in current production processes

-

Establish cross-functional teams including engineering, biology, and sustainability experts to identify biomimetic opportunities

-

Develop specialized metrics that capture total lifecycle benefits rather than just immediate production costs

-

Create a biological model database relevant to your manufacturing challenges for ongoing innovation

-

Partner with universities and research institutions with specialized expertise in biomimicry and biologically-inspired design

-

Consider both product design and process optimization applications simultaneously to maximize return on investment

The adoption of biomimicry in manufacturing represents not merely an incremental improvement but a fundamental reimagining of industrial production principles. By aligning manufacturing systems with patterns and processes refined through billions of years of natural evolution, companies gain powerful tools for addressing contemporary challenges ranging from resource constraints to environmental impacts. As implementation barriers continue to fall and success stories multiply across diverse sectors, nature-inspired manufacturing approaches will likely transition from competitive advantage to industry standard. Organizations that develop biomimetic expertise today position themselves advantageously for the more resource-constrained and environmentally-regulated manufacturing landscape of tomorrow.